Aerovac Peel Ply

Aerovac Peel Ply Meets a Wide Variety of Composites Manufacturing Needs

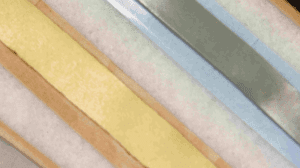

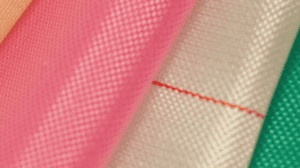

Aerovac peel ply products by are available in multiple materials and formats to offer flexibility in options and to match specific application requirements. Our woven peel ply fabrics range from light to heavyweight and are available as both nylon peel ply and polyester. Some offer adhesive backing which helps simplify the application process while release coated peel plies make removal much easier. Choose from standard formats, slit width, or cut-to-shape formats for nylon peel ply fabric and other options. Coarse and fine weaves are also available.

Product Benefits of Aerovac’s Peel Ply

Peel ply creates a textured surface on the composite, improving adhesion of subsequent layers, adhesives, or paints. Additionally, it can also help prevent excess resin accumulation, reducing the final part weight. When selecting a peel ply it is important to consider the tightness of the weave and the weight of the material because both will affect the final appearance and performance of the composite part. The right selection can help create a more consistent surface finish, and as a result, a more attractive product.

Using Peel Ply for Fiberglass and other Composites

Peel ply material is used in several different composite manufacturing processes. For example, the use of peel ply in vacuum bagging of prepreg or wet-preg and vacuum infusion processing are common applications. It is also used in other processes such as glass lamination and compression molding. For vacuum bag cure of prepreg or wet-preg, peel ply is placed against the final prepreg layer. Afterwards, it is covered with a release film and breather material. When used on composites, peel ply, release film, and breather helps to remove gases and excess resin from the laminate.

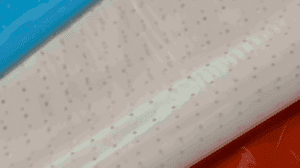

For vacuum infusion of composites, peel ply is placed against the last layer of dry fiber reinforcement. It can be covered with a flow media, such as Infuply2 or VI10. In addition to leaving a nice texture for subsequent processing, the peel ply allows for easy removal of flow media and other process materials after the part is cured. Products are available with black or red pinstripes for easy identification on a cured composite part. It can also be left in place on the cured part to keep it clean of contaminants prior to subsequent processing.

How to Select the Right Peel Ply for Your Manufacturing Process

Our Technical Support Team can help assist you in selecting the ideal Aerovac peel ply for your specific application. Aerovac offers a wide range of peel ply products including peel ply tape as well as combination products such as Vac-Ply Combi 1. This product combines perforated release film, knitted infusion mesh, and peel ply for polyester resin infusion applications in temperatures up to 248°F.

Explore products below and download technical data sheets on-demand. Aerovac polyester peel ply, nylon peel ply and other process materials are available through Composites One in North America or through Aerovac’s Distribution Network globally. To learn more about what we have to offer, get in touch with one of our worldwide locations or contact us online to request a quote.

Aerovac Peel Ply Products

For more detailed information about each product, fill out the form below the product table to download the technical data sheet PDFs.

Product

Weight/Length

Description

A100PS

2.3oz/yd (80g/m)

White, medium weight, nylon with red pinstripe. Also strips cleanly and quickly from most commercial resin systems and works up to 400°F (204°C).

A100

2.3oz/yd (80g/m)

White, medium weight, nylon. Also strips cleanly and quickly from most commercial resin systems, working up to 400°F (204°C).

A100-1/A100-1PS

2.51oz/yd² (80g/m²)

Porous polyamide 6 peel ply. A100-1 is white. A100-1PS is white with red pin stripes. Recommended for composite manufacture and metal bonding applications up to 400°F (204°C).

A100/A100PS ECO

2.51oz/yd² (80g/m²)

Porous nylon PA56 peel ply. A100 ECO is white. A100PS ECO is white with red tracer. Recommended for composite manufacture and metal bonding applications up to 400°F (204°C).

A100FLOGREEN

2.3oz/yd (80g/m)

Fluorescent green, medium weight, nylon, easily visible and strips cleanly and quickly from most commercial resin systems, working up to 400°F (204°C).

B100

1.7oz/yd (60g/m)

White, lightweight nylon, strips cleanly and quickly from most commercial resin systems, working up to 400°F (204°C).

D300

2.8oz/yd (94g/m)

Pink, medium weight nylon 6.6, easily visible and strips cleanly from most commercial resin systems, works up to 400°F (204°C).

F400

2.9oz/yd (100g/m)

White, heavyweight polyester which is recommended for use with a range of commercial systems, including phenolic resins, works up to 356°F (180°C).

60001

2.5oz/yd (85g/m)

White, medium weight polyester which also strips easily and cleanly from a range of commercial systems, including phenolic resins. Approved on various aerospace specifications, suitable for use up to 400°F (204°C).

51789

1.9oz/yd (65g/m)

Medium weight nylon 6.6 for use directly against laminates or bond lines, imparting a very fine weave pattern upon removal from the laminate. Approved on various aerospace specifications and can be used up to 450°F (232°C).

52008

1.7oz/yd (60g/m)

Lightweight nylon 6.6 which has been heat set and scoured for use directly against laminates or bond lines. Imparts a very fine weave pattern upon removal from the laminate and can be used up to 450°F (232°C).

VAC-PLY COMBI 1

6.93oz/yd² (235g/m²)

Polyethylene and nylon, perforated release film combined with knitted infusion mesh and peel ply. Temperature resistance up to 248°F (120°C).