Wind Turbine Composite Material Supplier

Cost-Effective Performance for Wind Turbine Manufacturing

Aerovac is at the forefront of the Wind Energy market delivering the necessary process materials required to meet the demand for power generation. Our continuous product development delivers cost-effective performance for the manufacture of large structures.

- Supply the majority of OEM and contracted blade and nacelle manufacturers

- Full product line availability

- Customized kits

- Technical plant audits focused on finding cost reduction opportunities

- Now includes local and logistics in North America

- Dependable service

Why Aerovac for Wind Energy?

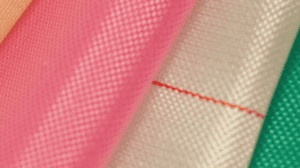

Wind and other sustainable energy sources are rapidly becoming a larger part of the overall power supply. Aerovac has the products and technical support necessary to help manufacturers be successful. Vacuum Infusion is ideally suited for the manufacture of composite wind blades and other innovative energy generating solutions like wave and tide technology. With increasing reliance on sustainable and renewable energy sources, worldwide governments and power generators are incorporating these processes to help the manufacturer make stronger, lighter, and longer lasting wind blades. Aerovac Process Materials provide solutions to wind and other power generation industries with unmatched technical assistance, kitting solutions and logistical support. Aerovac Composites One technical experts help guide wind engineers in product selection, design, and manufacturing.

Innovating Wind Blades for a Sustainable Future

As the wind power industry continues to grow, there is an increasing demand for new innovations to make blades stronger, lighter and more sustainable. Aerovac is proud to be on the cutting edge of the industry, staying in step with all the latest developments that are expected to have a transformative effect on the marketplace and enhance the viability of wind energy as a renewable resource.

For example, new advancements in nanotechnology are enabling the creation of carbon nanotubes that can significantly improve the strength and durability of wind composites. Hybrid wind turbine composites that combine carbon and glass fibers also help cut down on the manufacturing costs for these components, making the technology more cost-effective and lowering the barrier to entry.

In terms of making wind turbine manufacturing more sustainable, there are many exciting advancements currently taking place in the industry. These include the development of composite materials for wind turbine blades using natural fibers such as bamboo to replace synthetics, as well as turbine blade additive manufacturing techniques that reduce the amount of waste generated by blade production. These also are expected to have the added benefit of creating blades with more-precise specifications for enhanced performance.

Navigating Regulatory Challenges

Another area where Aerovac is paying close attention is the growing concern about what to do with decommissioned composite wind turbine blades. Because the materials used in their construction can be challenging to recycle, many states are considering legislation pertaining to their manufacturing and disposal.

Fortunately, Aerovac joins many others in the composites industry in seeking sustainable solutions that lessen these concerns and comply with current and anticipated regulations. Whether the solution includes biodegradable materials, enhanced recycling efforts, or a combination of techniques, Aerovac stands ready to do our part in keeping the wind energy industry compliant and prepared for whatever regulatory challenges it may face.