Aerospace

Cutting Edge Products for Aerospace Manufacturing

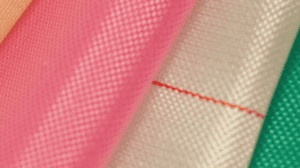

Aerovac delivers high-performance products and kitting to manufacturers while maintaining cost savings. Aerospace composites manufacturing processes include prepreg processing, vacuum infusion, glass lamination, and others. Aerovac combines high-quality vacuum bagging and process materials, with industry leading technical support to help aviation manufacturers reach their goals. We offer:

- Material Management Solutions

- Full product line availability

- Many specifications in place

- Focused technical experts

- Customized kits

- Local and expanded logistic solutions in North America

- Dependable service

Global Certifications

Aerovac is positioned to service the aerospace market with required certifications including the AS9120 certification. This is the Quality Management Standard specific to military, defense, and aerospace for distributors. Maintaining this high level of certification ensures manufactures can feel especially confident in a partnership with Aerovac.

These certifications in addition to freezer capacity and a privately own fleet of delivery trucks, ensures customers can trust in reliable and safe storage of products and reduced lead times.

AS9210

AS9100

EN9100

SO 9001

Why Aerovac for Aviation?

Aerospace and aviation industries operate on the cutting-edge of advanced composites, demanding high-performance products that are lightweight and high strength. Aerovac offers all the necessary vacuum bagging and process materials for the manufacture of composite aerospace and aircraft components including general aviation, commercial aircraft, military aircraft, and spacecraft applications. Our full range of materials include those for high-temperature cure epoxy, cyanate ester and BMI composites matrices. The legacy of Aerovac Process Materials in addition to the depth and breadth of the Composites One product line combine perfectly to ensure aviation manufacturers consistently produce quality parts.